Real Time X-Ray Systems

Euroteck Systems offer a complete range of real time X-ray systems from 160kV to 450kV. Multiple axis systems with manual and CNC control are available for the inspection of Automotive, Aerospace and Electronic and Cast components.

Euroteck have been the UK distributor for Bosello HT for more than 15 years and we have a great deal of experience in helping customers to choose the correct solution for their application.

Bosello have been building and supplying X-ray systems for the worldwide market for more than 25 years and are now one of the biggest manufacturers of real time X-ray systems.

We can supply a standard range of real time inspection systems, each of which can be tailored to suit individual customer requirements.

For customers who need a bespoke X-ray system, we can begin with a blank piece of paper and design a special solution. We can do this because mechanical and electrical design and software development are all carried out in-house at Bosello HT.

Certain Bosello X-ray machines can be supplied with optional:

- Automatic Defect Recognition (ADR). ADR speeds up the inspection process by applying a predefined acceptance criterion to regions of interest applied to the part.

- Computed Tomography. SRE Max systems can be supplied CT ready, requiring only the addition of CT software such as Volume Graphics CT package to enable the SRE Max to generate CT data. These systems should not be confused with micro-CT systems, more of which can be seen on our Computed Tomography page.

SRE Max

The SRE Max range are X-ray shielded cabinets that comply with Italian regulation (DPR 257/2001) and the strictest international regulations for fully shielded radiation devices. The cabinet is completely self-contained. Manufactured in steel with complete lead shielding. The cabinet can be transported by fork-lift. The cabinet does not require any further shielding and can be located safely in any workplace area

Key features:

-

- The cabinet is designed with large double sliding doors for part loading with two Lead/glass inspection windows. High speed door movement is controlled by an inverter. A safety light curtain on the loading door prevents trapped hands.

- The inspection positions are obtained by the movement of the complete X-ray system without any C-Arm. Coordination and alignment between source and the detector is controlled by the software.

- This solution allows a significant increase in the speed of handling and positioning. The software allows the dynamic tilt axis in accordance with the part position on the zoom horizontal axis.

- The turntable can move on three axes with continuous rotation on 360º.

- A mechanical magnification axis guarantees linear and constant magnification factor.

- For ease of part loading, the turntable comes out from the loading door.

- Motorised and programmable two axes anti-blooming shutter.

- 7 independent handling axes (2 additional axes for motorised programmable shutter on X-ray source) are moved by brushless motors with absolute encoders on board. This equipment does not require zero setting (homing) of the axes.

- Positioning speed up to 15 metres/minute.

For further details on the SRE Max range, please visit the Download Page.

SRE Hex

The SRE Hex cabinet is completely self-contained. Manufactured in steel with complete lead shielding. The cabinet can be transported by forklift. It does not require any further shielding and can be located safely in any workplace area. Designed with double sliding doors for part-loading with a Lead/glass inspection window.

Key Features:

-

-

- The inspection positions are obtained by the movement of the complete X-ray system on the vertical axis, coordination and alignment between source and detector is controlled by the software (CNC version only). This solution allows a significant increase in the speed of handling and positioning. The software allows the dynamic tilt axis in accordance with the part position on the zoom horizontal axis.

- The turntable can move on 4 axes with continuous rotation on 360º.

- A mechanical magnification axis guarantees linear and constant magnification factor.

- Motorized and programmable two axes anti-blooming shutter.

- 6 independent handling axes (2 additional axes for motorized programmable shutter on X-Ray source), moved by brushless motors with absolute encoders on board. This equipment does not require zero setting (homing) of the axes.

- Positioning speed increased to 15 metres/min.

-

For further details on the SRE Hex range, please visit the Download Page.

Omnia

The Omnia is the newest addition to the Bosello real-time X-ray range. Designed primarily for fast continuous cycle inspections, it having been optimised to work in an automatic production line interfaced with an external robot.

The X-ray shielded cabinet complies with the strictest international regulations. It is completely self-contained, manufactured in steel with complete lead shielding. The Omnia does not require any further shielding and can be located safely in any workplace area.

Key Features:

-

-

- The pallets can be removed and changed in a few minutes without the need for special tools, this makes the Omnia very flexible to use with a wide variety of castings.

- Castings for inspection move from the outside to the inside inspection position by a rotating motorized mechanism with two pallets placed at 180º. This allows loading/unloading of the external pallet while the internal pallet is inspected. This allows high speed part changing typically 5 seconds or less, dramatically reducing the overall inspection time.

- The Omnia is designed with a pneumatic sliding door for casting loading, a large maintenance side door with a Lead glass inspection window.

- Optional safety light curtain or laser scanner on the loading area if the Omnia is to be manually loaded.

- The system is provided with an innovative Cross Over Twin Manipulator that allows the inspection positions to be obtained by the movement of the complete X-ray system without any C-Arm or other mechanical connection between the X-ray source and the detector. Coordination and alignment between source and detector are controlled by the software, and due to the high precision Cartesian manipulator to achieve any desired position including double tilting and zooming.

- Axes are controlled by brushless motors with absolute encoders on board. This means that the Omnia does not require any homing of the axes.

-

For further details on the Omnia range, please visit the Download Page.

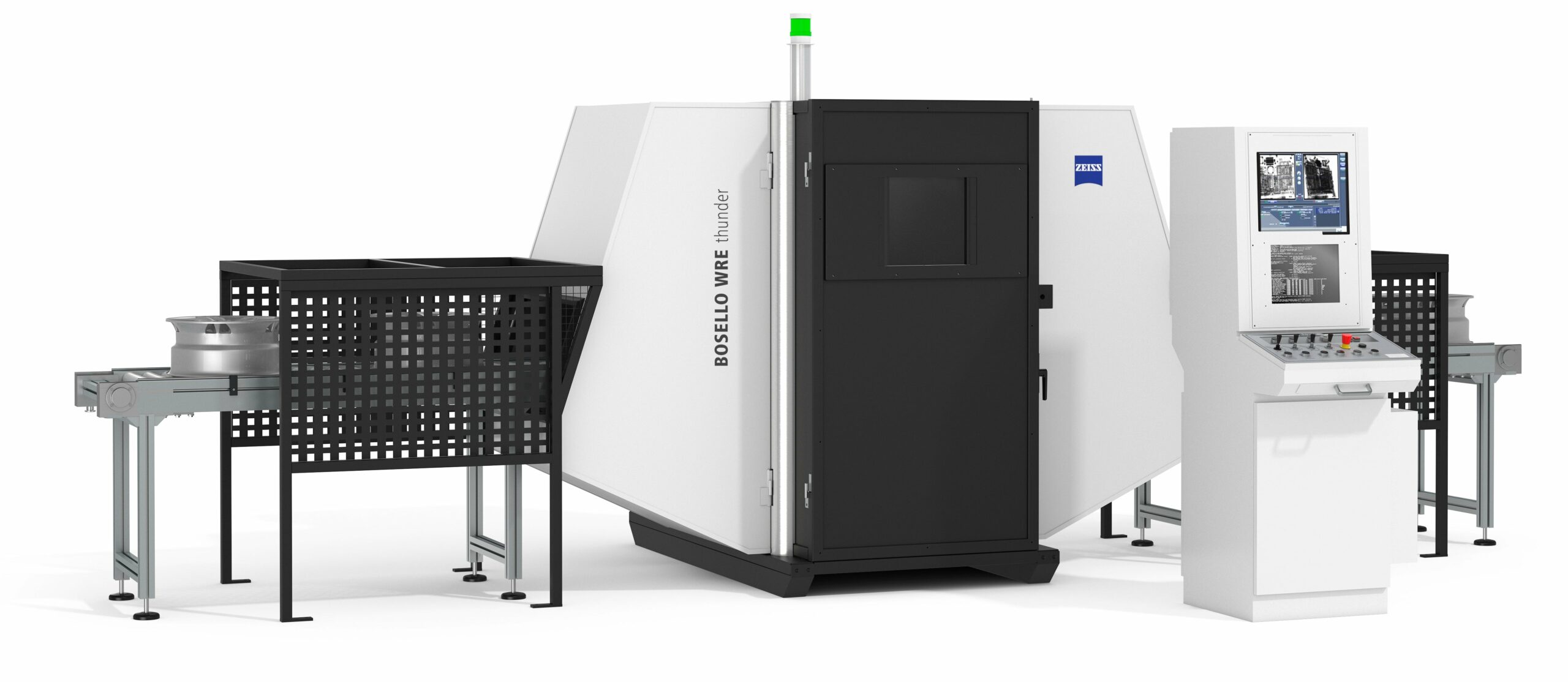

WRE THUNDER 3

The WRE THUNDER 3 equipment is the fastest solution for the online inspection of alloy wheels.

It has been designed to overcome the handling problems of large and heavy wheels up to 50kg.

Key Features:

-

-

- The machine has also been designed to cope with casting flash left on the wheel. This equipment has a strong and robust mechanical structure, designed for long and continuous use in the industrial environment.

- The WRE THUNDER 3 is very innovative because the inspection positions are obtained by the movement of the complete X-ray system without any C-Arm. The X-ray tube is moved by 2 handling axes and the Digital Imaging Panel is moved by 3 handling axes.

- Coordination and alignment between source and detector are controlled by software. This design concept allows a very compact cabinet to be built. The small dimensions allow customers to place it in confined spaces, installation is easy and the machine can be relocated quickly if necessary.

- This design solution has also allowed us to reduce to 2 seconds or less; the non-productive time (idle time). This makes our machine the fastest available on the market.

- Inspection capacity: Up to 145-off wheels per hour.

- There is no limit to the number of inspection programmes available, and a limit of 50 positions per programme.

- The Thunder 3 can be supplied with optional:

Automatic Defect Recognition (ADR). As described at top of the page. All automotive alloy wheel acceptance standards are supported.

Automatic Wheel Identifier (AWI) – System automatically detects which wheel is in the X-ray chamber and selects the correct programme for inspection.

-

Types of Wheels suitable for the WRE Thunder 3:

Standard WRE Thunder 3: 4J x 13” to 11J x 22”

WRE Thunder 3/T: 4J x 14” to 11J x 26”

Available for 2.4” motorbike wheels on request.

For further details on the WRE Thunder 3 system, please visit the Download Page.

Please do not hesitate to contact Euroteck Systems if you’d prefer to discuss your real time X-ray requirement.