Bespoke MPI/LPI Systems

Magnetic Particle/Dye Penetrant Systems

Euroteck Systems are now the UK and Ireland lead generator partner of CGM CIGIEMME S.p.A. based near Milan in Italy.

CGM have a long history of Magnetic Particle and Liquid Penetrant systems for NDT applications and celebrated their 60th anniversary in 2018.

Key markets for CGM systems are aerospace, steel testing, railway and automotive.

All MPI, LPI systems are manufactured on-site, and a factory acceptance test (FAT) carried out prior to the equipment being dismantled and shipped to the customer’s location.

Examples of recent MPI/LPI systems are shown below:

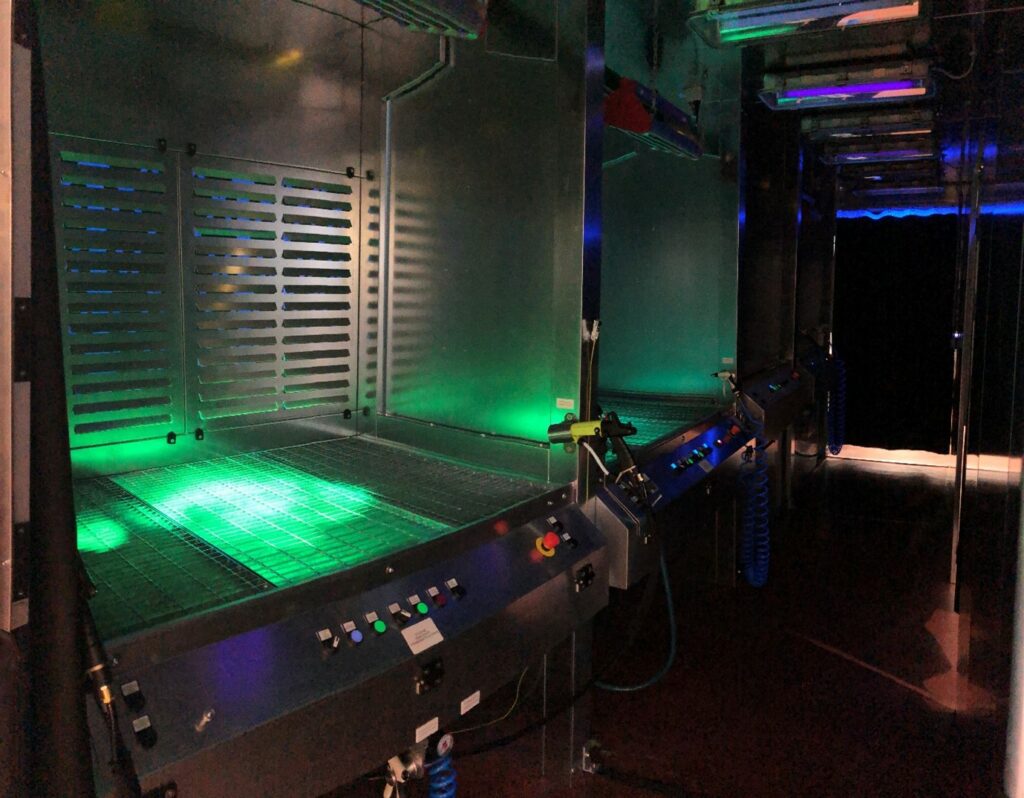

Aerospace Liquid Penetrant Inspection System:

The liquid penetrant inspection system was delivered to an aerospace company based in Germany.

The company specialises in the machining of Aeronautical components (rings, stator wheels, pump impellers, etc.)

CGM therefore designed and manufactured a complete fluorescent penetrant inspection line incorporating two types of fluorescent penetrant: water washable and post-emulsifiable applied using the electrostatic method.

This new penetrant system has allowed the aerospace company to increase throughput, eliminating the previous bottleneck of penetrant inspection.

Magnetic Particle Inspection Systems:

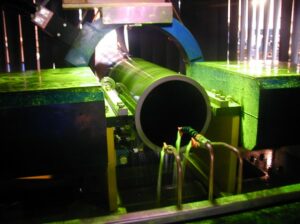

The MPI system shown below was custom designed and manufactured for railway axle inspection during the manufacturing process. The system can be upgraded with remote inspection technology using HDMI cameras.

The MPI system shown below was designed for semi-automated inspection of OCTG couplings. Together with MPI systems for pipe ends inspection, the MPI system for couplings makes up a complete solution for pipe manufacturing plants (Oil & Gas).

Aerospace MPI system:

The MPI bench below was designed and manufactured to inspect aerospace turbine and compressor shafts. The system incorporated current flow, and encircling coils to inspect for longitudinal and transverse flaws. The novel design also includes a tilt facility use to spray and wet the inner surface of the shaft. The inclination together with shaft rotation ensured full magnetic liquid coverage of the inner surface. This aspect is crucial to guarantee good internal inspection by endoscope.

Please contact sales@euroteck.co.uk to discuss your MPI/LPI system requirements in more detail.